HONEYSTONE

About us

Honeystone Ltd. supplies equipment for Thick Film hybrid technology and semiconductor packaging worldwide. Our qualified engineers provide installation, warranty, and lifetime maintenance support.

With strong engineering expertise, we offer cost-effective project assistance, technical consulting, and support during product development and proof-of-concept stages.

Across markets, we act as representatives and consultants for equipment and materials manufacturers, delivering application advice, sales, and full service throughout the asset's life cycle.

About us

Honeystone Ltd. supplies equipment for Thick Film hybrid technology and semiconductor packaging worldwide. Our qualified engineers provide installation, warranty, and lifetime maintenance support.

With strong engineering expertise, we offer cost-effective project assistance, technical consulting, and support during product development and proof-of-concept stages.

Across markets, we act as representatives and consultants for equipment and materials manufacturers, delivering application advice, sales, and full service throughout the asset's life cycle.

Chip Resistors

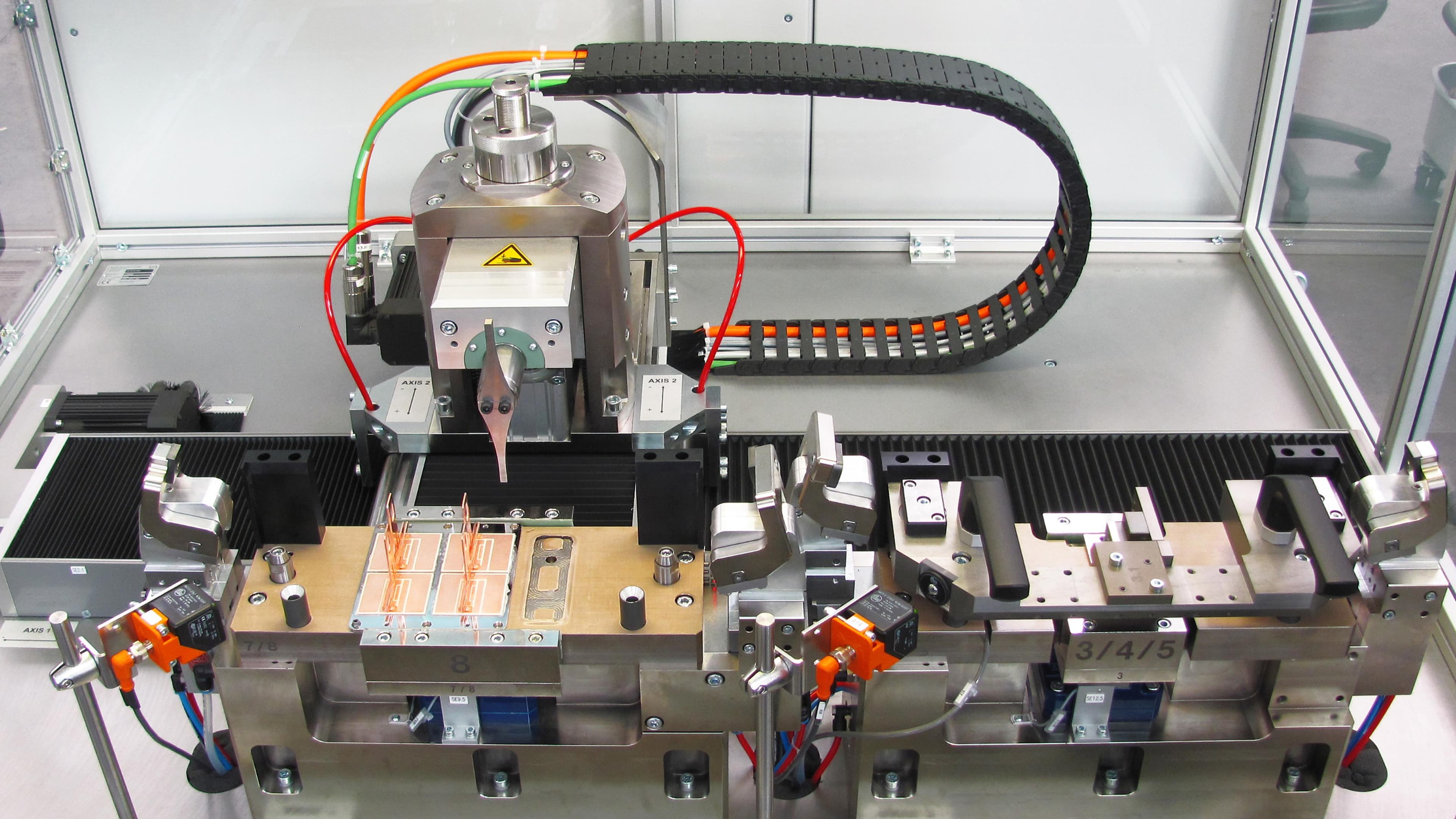

Turn Key manufacturing lines for high precision, high mix low-volume chip resistor production

Videos

Belt Furnaces from Hengli Eletek

Aurel standart product line

Thick Film Manufacture

Hengli 2025

Our services

Turnkey production equipment supply and service worldwide Process development and Product design assistance

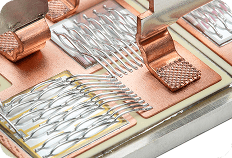

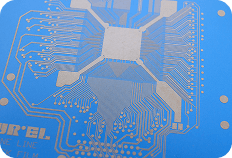

Thick Film Hybrids

Classic Thick Film

screen fabrication, printing, drying, firing, trimming, optical inspection, calibration, sorting, and environmental testing.

Fine Line Thick Film

use of photoimageable pastes, exposure, and development for precise circuit patterns.

Multilayer Ceramic Processes

processing, assembling, and sintering of complex multilayer electronic structures.

Heterogenous Structures, composites and batteries

Glass Feed-throughs GTMS/HTCC

glass-to-metal sealing, kovar ring and leadframe brazing and plating.

DBC/AMB Substrates

oxidation, sputtering, copper bonding, photolithography, etching, and plating for power electronics.

SOFC and Hydrolisers

Cell ink and ceramic slurry manufacturing, screen printing, dispensing or casting, stacking layers, hermetic sealing and the final assembly

Battery Active Materials

Milling, mixing and drying of cathode and anode materials, conveying and thermal treatment in calcination kilns, complete factory solutions for LFP Gen 3 and 4, MLFP, NCM, Sodium cathodes, graphite, composite Si-C and metal oxide anodes

Back-End Advanced Packaging

Cutting, scribing, heat treatment (vacuum, inert or reducing gases).

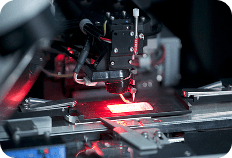

Die bonding, microassembly, fluxless soldering.

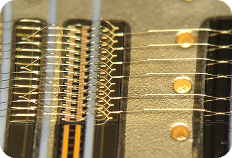

Wire bonding, laser welding for high-power products.

Hermetic sealing of cases in a controlled atmosphere.

Forming cases on leadframes, testing (electrical, structural, environmental).

Our Recent Projects Worldwide

Training Programs

The unique proposition is our independent advice Operator and process technician training programs Process audits and Coached production at the Customer's facility.

Training Programs at affordable daily rate

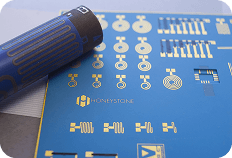

Screen Manufacture Process

From frame and mesh selection to proper storage, step by step materials guide and process set up

Firing Furnace Set up

Air pressure and flow adjustment methods, temperature profiling and verification

Design Rules

Thick and Thin Film process limitations and pitfalls

Screen Printing

Up to 70% of defects can be eliminated by optimisation of screen printing parameters

Thick Film Process documentation

A set of Process Instructions in either paper or electronic interactive format based on ScanCAD ™ ProWorks ™ platform

Coached Production

New Product launch assistance, manufacturing of samples and production ramping up at the Customer's site

Our location

Honeystone Limited

Ground Floor,

123 Pall Mall SW1Y 5EA London UK

Follow the news in our

Linkedin profile